Komtac|Dongcheng

Dongze|Huaisong

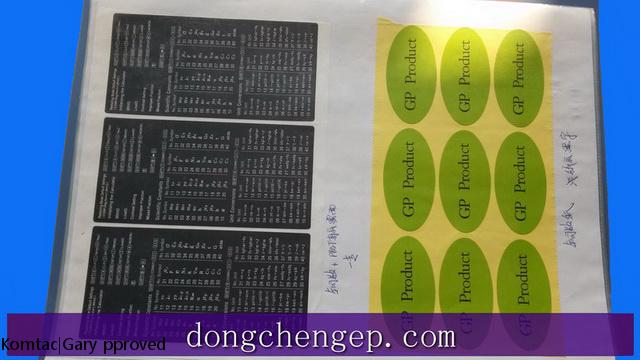

sticker and label service

Quality Customized Labels Printing Service And Label Sticker Maker

|

Product name |

Custom Adhesive labels |

|

Material |

PVC/PET/BOPP/Special paper/Coated paper/Aluminium-foil paper/Synthetic paper |

|

Color |

Customized |

|

Shape |

Custom Shape |

|

Size |

Customized |

|

Feature |

Eco-friendly, water-proof, strong permanent glue |

|

Surface finishing |

Glossy/Matt coating or lamination,Hot stamping,/Embossed/UV coating |

|

Printing |

CMYK Printing,Up to 8 colors |

|

Application |

Water bottles,Wine bottle, food Jar,sauce bottle,cosmetic,medical etc., packaging ,can be widely used. |

|

Sample time |

5 to 7 days |

|

Lead time |

10 to 20days (the exact should according to the order qty) |

|

Packaging |

Put in normal export carton |

|

|

|

The characteristic for Plastic vs. Paper Stickers and Labels: A Comparative Guide to Choosing the Right Option

Introduction

Stickers and labels are integral to product packaging, marketing, and organization across various industries. They serve a multitude of purposes, from branding and information dissemination to decorative accents and logistical tracking. When selecting stickers and labels, the choice between plastic and paper materials is crucial, as each offers distinct advantages and limitations. This article explores the key differences between plastic and paper stickers and labels, helping you make an informed decision based on your specific needs and applications.

Plastic Stickers and Labels

1. Characteristics:

- Material Composition: Made from synthetic materials such as vinyl, polyester, or polypropylene, plastic stickers and labels are known for their durability and resistance to various environmental factors.

- Durability: Plastic labels are highly resistant to water, chemicals, UV light, and abrasion, making them suitable for harsh conditions and long-term applications.

- Flexibility: Plastic materials can be manufactured in various finishes, including gloss, matte, and clear, offering versatility in design and appearance.

2. Benefits:

- Weather Resistance: Ideal for outdoor use or applications where exposure to moisture or sunlight is a concern. Plastic stickers and labels maintain their integrity and appearance even under challenging conditions.

- Longevity: The durability of plastic ensures that stickers and labels remain intact and legible over time, making them suitable for products with long shelf lives or extended use.

- Customizability: Available in various shapes, sizes, and finishes, plastic labels can be easily customized with vibrant colors, intricate designs, and high-resolution graphics.

3. Applications:

- Product Labels: Used for branding, product information, and safety warnings on consumer goods, especially those exposed to moisture or chemicals.

- Outdoor Signage: Ideal for creating durable and weather-resistant signs and decals for outdoor use.

- Industrial Labels: Suitable for labeling machinery, equipment, and parts in industrial settings where durability is essential.

Paper Stickers and Labels

1. Characteristics:

- Material Composition: Made from paper or paperboard, these stickers and labels are often coated with a protective layer to enhance their performance and appearance.

- Print Quality: Paper labels generally offer high print quality with crisp, vibrant colors and fine details, making them ideal for detailed graphics and text.

- Cost-Effectiveness: Paper stickers and labels are typically more affordable compared to plastic options, making them a budget-friendly choice for various applications.

2. Benefits:

- Eco-Friendly Options: Many paper stickers and labels are made from recycled or sustainably sourced materials, making them a more environmentally friendly choice.

- Ease of Printing: Paper labels are easy to print on using standard inkjet or laser printers, allowing for quick and cost-effective customization.

- Versatility: Available in a wide range of finishes, including matte and gloss, paper labels can be used for various applications and decorative purposes.

3. Applications:

- Retail and Packaging: Commonly used for product labeling, barcodes, and promotional stickers on packaging.

- Office and Home Use: Ideal for organizing files, folders, and personal items, as well as for crafting and DIY projects.

- Promotional Materials: Often used for giveaways, event branding, and marketing materials where cost-effectiveness and aesthetic appeal are key.

Comparing Plastic and Paper Stickers and Labels

1. Durability:

- Plastic: Offers superior durability and resistance to environmental factors, making it suitable for applications where longevity and toughness are required.

- Paper: Generally less durable and more susceptible to damage from water, chemicals, and wear, making it better suited for indoor or low-exposure applications.

2. Cost:

- Plastic: Typically more expensive due to the higher cost of materials and manufacturing processes.

- Paper: Generally more affordable, making it a cost-effective option for large volumes or short-term use.

3. Environmental Impact:

- Plastic: While some plastic labels are recyclable or made from recycled materials, the environmental impact of plastic is a concern due to its non-biodegradable nature.

- Paper: Often considered more eco-friendly, especially if made from recycled or sustainably sourced materials, and is biodegradable.

4. Customization and Aesthetics:

- Plastic: Offers high-quality printing with a wide range of finishes and can handle complex designs and high-resolution graphics.

- Paper: Provides excellent print quality with vibrant colors and fine details, and is available in a variety of finishes to match different design preferences.

Conclusion

Choosing between plastic and paper stickers and labels depends on various factors, including the specific application, environmental conditions, budget, and desired aesthetics. Plastic stickers and labels offer durability and resistance to harsh conditions, making them ideal for long-term and outdoor applications. On the other hand, paper stickers and labels are cost-effective and environmentally friendly, suitable for indoor use and situations where print quality and affordability are prioritized.

By understanding the characteristics, benefits, and applications of both materials, you can make an informed decision that best suits your needs, ensuring that your stickers and labels not only meet functional requirements but also enhance the overall presentation and effectiveness of your products or projects.

Address:3FL,Blck A#,Huimei Industry Park,Luwu, Zengbu, Chashan, Dongguan, Guangdong, China

Post Code:523383

E-mail: gary@dongchengep.com

Tel:+86-769-81800502

Mobile:+86-13712658816

Mr Gary shaw