Komtac|Dongcheng

Dongze|Huaisong

_1it2.jpg)

_1it2.jpg)

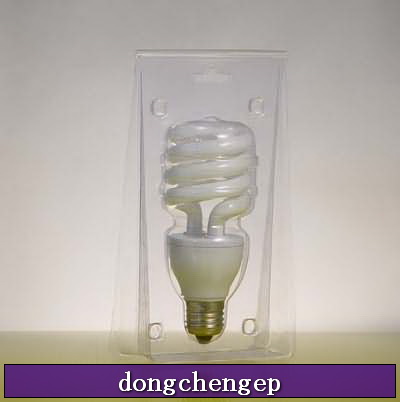

| Forming shape | tray,box,clamshell,tray with fold edge |

| Application | suite for comunication products,Consumer Electronics Products,cosmetics products battey,toy,harwardware components.. |

| Function | protect goods,fix products,Anti-static,cushion.. |

|

Material

|

PS,PVC,PP,PE,PET,HIPS,APET,PETG,PLA ,FLOCKING material

|

| Thickness | Customized ,Gerenal range 0.3-1.5mm |

| No ESD | 10^0-10^4ohm |

|

ESD /Resistance

|

10^5-10^9ohm,10^9-10^11ohm

|

| Printing | special required with screen printing or printing label |

| Environmental friendly | SGS,ROHS,REAH,HF if special need |

|

Color

|

Customized,black,clear,yellow,black,brown,white,brigt blue….

|

|

Size

|

Customized

|

Mobile phone, computer, home appliances, precision instruments, and other electronic products export growth year by year, also contributed to the Electronics Packaging's fast development. The product of the boxes and needed to cushion, pallets packaging materials, manufacturing process improvement, technical level and product quality continuously improve.

Relative to other goods more concerned, electronic products for precision components, in handling, transport, storage and process vulnerable to vibration or shock and damage, another part of the product will be because the change damp or temperature and humidity affect its performance. So the packaging for electronic product, should have a high strength and buffering properties, impact resistance and compression performance better.

We in the production line of the reasonable technical improvement, the introduction of new manufacturing process and technology.We are manufacturer and supplier of Electronics Packaging. We dedicate ourselves to manufacture and supply of Electronics Packaging with nice service. If you want to get more information of our products, you can view our thermoformed packaging.We eare always welcome your inquiry and build a business relationship.

Our partners :

Lite-On Group, Foxconn Group, Kyocera Mita, VTech,

Delta, BYD,Cnbooker Group,Szeina,

Xiaomi.Lenevo,Molex,Panassoinc,

Primax,ZTE,Samsung,HP,

Philips,Jabil,TE Connectivity(TYCO),Universal Electroincs(UCIE),

Meizu.Amazon.UBNT.

_ftu6.jpg)

_k7ux.jpg)

_vx8f.jpg)

Vacuum Thermoforming ESD Foldable Trays: Advanced Solutions for Electronic Component Packaging

Introduction

In the specialized realm of electronic component packaging, ensuring both protection and efficiency is crucial. Vacuum thermoforming ESD (Electrostatic Discharge) foldable trays offer an innovative solution that addresses these needs with precision and versatility. These trays are designed to protect sensitive electronic components from electrostatic discharge while providing the added benefits of foldability for space-saving and efficiency. This article explores the features, advantages, and applications of vacuum thermoforming ESD foldable trays, highlighting their importance in modern electronics packaging.

What are Vacuum Thermoforming ESD Foldable Trays?

Vacuum thermoforming ESD foldable trays are advanced packaging solutions created through a specialized thermoforming process combined with ESD protection features. These trays are designed to be folded for compact storage and transport, offering a space-efficient solution for handling electronic components. The vacuum thermoforming process ensures precision molding, while the ESD protection features safeguard sensitive components from electrostatic damage.

1. Material Composition:

- Plastic Sheets: Made from ESD-safe plastics such as ESD PET (polyethylene terephthalate) or ESD PVC (polyvinyl chloride), which are designed to prevent the accumulation and discharge of static electricity.

- Thermoforming Process: Involves heating the plastic sheet until it becomes pliable, then using vacuum pressure to mold it into the desired shape, followed by cooling to retain the form.

2. Design Features:

- Foldable Structure: Trays are designed to be folded, allowing for compact storage and efficient use of space during transport and storage.

- ESD Protection: Incorporates conductive or dissipative materials to protect electronic components from electrostatic discharge, which can cause damage or malfunction.

- Customizable Compartments: Features custom-designed compartments and dividers to securely hold and organize various electronic components.

Benefits of Vacuum Thermoforming ESD Foldable Trays

1. Enhanced ESD Protection:

- Static Discharge Prevention: The ESD-safe materials used in the trays help prevent static build-up and discharge, protecting sensitive electronic components from potential damage.

- Compliance: Meets industry standards for ESD protection, ensuring that electronic components are stored and transported in a manner that minimizes risk.

2. Space Efficiency:

- Foldable Design: The ability to fold the trays allows for efficient use of storage space and reduces shipping costs. This feature is particularly advantageous for high-volume operations where space and cost efficiency are critical.

- Stackability: Foldable trays can be stacked when not in use, further optimizing storage and transportation space.

3. Precision and Customization:

- Accurate Molding: The vacuum thermoforming process ensures precise molding, resulting in trays that fit electronic components perfectly and securely.

- Custom Compartments: Can be customized with various compartments and dividers to accommodate different types and sizes of electronic components, enhancing organization and protection.

4. Durability and Reliability:

- Robust Construction: Made from durable ESD-safe plastics, these trays are designed to withstand the rigors of handling, transportation, and storage.

- Impact Resistance: Offers resistance to impact and other environmental factors, ensuring that electronic components remain protected.

5. Cost-Effectiveness:

- Efficient Production: The thermoforming process is cost-effective for producing high volumes of trays, making it an economical choice for large-scale operations.

- Reduced Waste: Precision molding and efficient use of materials help minimize waste, contributing to cost savings and sustainability.

Applications of Vacuum Thermoforming ESD Foldable Trays

1. Electronics Manufacturing:

- Component Handling: Ideal for packaging and organizing electronic components during manufacturing, assembly, and testing processes. Ensures that components are protected from electrostatic discharge and are easily accessible.

- Component Storage: Used for storing electronic parts in warehouses and distribution centers, providing protection and efficient space utilization.

2. Electronics Distribution:

- Transport Packaging: Provides a secure and efficient packaging solution for transporting electronic components from manufacturers to distributors and retailers. The foldable design helps reduce shipping costs and optimize space.

- Retail Display: Can be used for retail packaging, allowing for organized and attractive presentation of electronic components.

3. High-Tech Industries:

- Sensitive Equipment: Suitable for packaging sensitive high-tech equipment and components that require protection from electrostatic damage. Ensures that components remain in optimal condition during handling and transportation.

- Custom Solutions: Can be tailored to meet the specific requirements of various high-tech industries, including aerospace and telecommunications.

4. Consumer Electronics:

- Product Packaging: Used for packaging consumer electronics such as smartphones, tablets, and accessories. Provides protection and organization, enhancing the presentation and safety of the products.

- Accessory Storage: Ideal for organizing and storing electronic accessories, such as chargers and cables, ensuring that they are protected and easily accessible.

5. Testing and Research:

- Lab Storage: Provides secure and organized storage for electronic components and devices used in testing and research environments. Ensures that components are protected from static discharge and damage.

- Component Organization: Helps organize components during research and development phases, improving efficiency and accuracy.

Innovations and Future Trends

1. Advanced ESD Materials:

- Enhanced Protection: Development of new ESD-safe materials with improved conductivity and dissipative properties to provide even better protection for electronic components.

- Eco-Friendly Options: Exploration of sustainable ESD materials to support environmental goals and reduce the impact of packaging.

2. Smart Packaging:

- Integrated Technology: Incorporation of technologies such as RFID tags or QR codes for tracking and inventory management of electronic components.

- Temperature Control: Development of trays with built-in temperature control features to protect sensitive components from temperature fluctuations.

3. Customization and Personalization:

- Bespoke Designs: Increasing demand for customized and personalized trays to meet specific requirements and branding needs.

- Advanced Printing: Use of high-resolution printing techniques to enhance product presentation and branding.

4. Regulatory Compliance:

- Evolving Standards: Ongoing updates to meet evolving industry standards and regulations for ESD protection, ensuring that packaging solutions remain compliant and effective.

Conclusion

Vacuum thermoforming ESD foldable trays represent a sophisticated and efficient solution for packaging electronic components. Their combination of ESD protection, space efficiency, precision, and customization makes them an essential tool in the electronics industry. As technology and sustainability efforts continue to drive innovation, these trays are likely to see further advancements, enhancing their role in providing reliable and effective packaging solutions. Whether for manufacturing, distribution, or retail, vacuum thermoforming ESD foldable trays play a crucial role in ensuring the safety, organization, and efficiency of electronic component packaging.

Address:3FL,Blck A#,Huimei Industry Park,Luwu, Zengbu, Chashan, Dongguan, Guangdong, China

Post Code:523383

E-mail: gary@dongchengep.com

Tel:+86-769-81800502

Mobile:+86-13712658816

Mr Gary shaw

_94e6.jpg)

_4g64.jpg)

_qn1w.jpg)

_3okr.jpg)

_l7du.jpg)

_4y15.jpg)

_4z07.jpg)

_tj3d.jpg)

_xlj0.jpg)

_o104.jpg)

_ziff.jpg)

_n8gu.jpg)

_9x87.jpg)

_10b4.jpg)

_wgy2.jpg)

_58by.jpg)

_67j3.jpg)

_4b84.jpg)